Call Us: (302) 425-4400

About Us

ABOUT US

Today's ULSD (ultra low sulfur diesel) blends have changed the fuel industry considerably. Stabilizers are less relevant to the ULSD blends and biocides do not dissolve or eliminate sludge problems. Polishing diesel fuel simply centrifuges sludge out of the fuel into a filter system but does not resolve sludge issues.

Sludge is a microbial phenomenon and only Fuel Right has the right combination of ingredients to deal with sludge, corrosion and fuel line freeze-ups.

Sludge is a microbial phenomenon and only Fuel Right has the right combination of ingredients to deal with sludge, corrosion and fuel line freeze-ups.

Developed over the past two decades, Fuel Right Chemistry is unique and uses a powerful combination of amines to slowly dissolve existing

sludge, while preventing growth and build-up of new sludge. These amines also protect tanks and fuel system components from corrosion, even in the presence of free water and remaining old sludge. Fuel Right also improves lubricity thus extending the service life of injection pumps and other high wear fuel components. Fuel Right contains glycol ether, a necessary ingredient that protects against fuel line freeze-ups in cold weather climates.

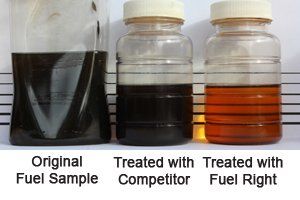

Proven in laboratory testing over the past 16 years, Fuel Right has been tested against more than 85 competitive products and has out-performed everyone.

OUR COMMITMENT

At Fuel Right, we are committed to an effort of continuous improvement of our technology in an ever changing fuel industry. Fuel Right was the first to identify the causes of sludge formation in fuel systems as well as treatments to dissolve and prevent further sludge growth.

Fuel Right was the first to develop a test protocol that documents how Fuel Right and other fuel treatments actually perform in a real world environment. As a result, we are the first and only company to validate our claims and we have yet to find another product that performs as well as Fuel Right.

Our mission is to provide the best solution to sludge and fouling issues in fuel systems and to continually find ways to improve our performance.Bob Tatnall spent thirty years as a materials engineer with DuPont, specializing in corrosion, linings and coatings. In 1968 he first observed a little-known phenomenon called microbiologically influenced corrosion, or MIC. Fascinated by this destruction of metals and alloys by bacteria, Tatnall spent the rest of his DuPont career learning about how bacteria and other microorganisms interact in different environments. Through his collaboration with researchers at universities worldwide, he learned not only about bacteria, but also about biofouling, or the buildup of slime masses as a natural habitat for bacteria and fungi (yeasts and molds).

sludge, while preventing growth and build-up of new sludge. These amines also protect tanks and fuel system components from corrosion, even in the presence of free water and remaining old sludge. Fuel Right also improves lubricity thus extending the service life of injection pumps and other high wear fuel components. Fuel Right contains glycol ether, a necessary ingredient that protects against fuel line freeze-ups in cold weather climates.

Proven in laboratory testing over the past 16 years, Fuel Right has been tested against more than 85 competitive products and has out-performed everyone.

OUR COMMITMENT

At Fuel Right, we are committed to an effort of continuous improvement of our technology in an ever changing fuel industry. Fuel Right was the first to identify the causes of sludge formation in fuel systems as well as treatments to dissolve and prevent further sludge growth.

Fuel Right was the first to develop a test protocol that documents how Fuel Right and other fuel treatments actually perform in a real world environment. As a result, we are the first and only company to validate our claims and we have yet to find another product that performs as well as Fuel Right.

Our mission is to provide the best solution to sludge and fouling issues in fuel systems and to continually find ways to improve our performance.Bob Tatnall spent thirty years as a materials engineer with DuPont, specializing in corrosion, linings and coatings. In 1968 he first observed a little-known phenomenon called microbiologically influenced corrosion, or MIC. Fascinated by this destruction of metals and alloys by bacteria, Tatnall spent the rest of his DuPont career learning about how bacteria and other microorganisms interact in different environments. Through his collaboration with researchers at universities worldwide, he learned not only about bacteria, but also about biofouling, or the buildup of slime masses as a natural habitat for bacteria and fungi (yeasts and molds).

OUR FOUNDER

In 1980 Bob purchased an Oldsmobile diesel station wagon, and spent the next year fighting fouling of his fuel system by what he recognized as slime-forming bacteria. These bacteria were producing a dark, slimy mass we now know as "sludge". Through an associate he was introduced to a sludge-fighting fuel additive which helped to combat the issues he was having in his automobile.

In 1980 Bob purchased an Oldsmobile diesel station wagon, and spent the next year fighting fouling of his fuel system by what he recognized as slime-forming bacteria. These bacteria were producing a dark, slimy mass we now know as "sludge". Through an associate he was introduced to a sludge-fighting fuel additive which helped to combat the issues he was having in his automobile.

Two years later, after recognizing similar issues in his home-heating oil system and having endured fouled filters and plugged nozzles for a couple of seasons, he decided to apply the same diesel additive that had worked well in his Oldsmobile - and the sludge problem went away.

In 1991, Bob retired from DuPont and set out on his own as an MIC (since renamed "biocorrosion") expert. With few opportunities in this highly specialized field he decided to play around with sludge-control additives again, and Fuel Right was born.

The first generation of Fuel Right was simply the same diesel fuel treatment system that Bob had used to cure the problems in his car and home-heating system - a product which was made by a major international chemical company. Having a bit of Thomas Edison in his blood, he started taking this product apart and testing to determine how each part worked. Always seeking help from the world of chemists that he had met while with DuPont, he found new ingredients that made the product even better. Finding that the world had never developed a laboratory test to evaluate such products, Bob called on his early days as a test development engineer for DuPont, and designed today's "quart jar test". This comprehensive test evaluates additives to determine their ability to control sludge, fouling and corrosion in contaminated fuel systems. This test has become the basis for all product development, and no change is made to a Fuel Right product until it has demonstrated its benefit in this 18-month test.

Today's Fuel Right sludge/fouling/corrosion control treatment is the eighth generation of that ever-evolving product, and the current product line-up includes different specialized variations designed to solve various types of problems that occur in distillate fuels. In order to meet our high standards, all Fuel Right products must prove in controlled tests that they actually do what they claim to do, and they must do it better than any other product on the market. If Bob can't meet both of those objectives, then he simply recommends competitors' products to fill those needs.

In 1991, Bob retired from DuPont and set out on his own as an MIC (since renamed "biocorrosion") expert. With few opportunities in this highly specialized field he decided to play around with sludge-control additives again, and Fuel Right was born.

The first generation of Fuel Right was simply the same diesel fuel treatment system that Bob had used to cure the problems in his car and home-heating system - a product which was made by a major international chemical company. Having a bit of Thomas Edison in his blood, he started taking this product apart and testing to determine how each part worked. Always seeking help from the world of chemists that he had met while with DuPont, he found new ingredients that made the product even better. Finding that the world had never developed a laboratory test to evaluate such products, Bob called on his early days as a test development engineer for DuPont, and designed today's "quart jar test". This comprehensive test evaluates additives to determine their ability to control sludge, fouling and corrosion in contaminated fuel systems. This test has become the basis for all product development, and no change is made to a Fuel Right product until it has demonstrated its benefit in this 18-month test.

Today's Fuel Right sludge/fouling/corrosion control treatment is the eighth generation of that ever-evolving product, and the current product line-up includes different specialized variations designed to solve various types of problems that occur in distillate fuels. In order to meet our high standards, all Fuel Right products must prove in controlled tests that they actually do what they claim to do, and they must do it better than any other product on the market. If Bob can't meet both of those objectives, then he simply recommends competitors' products to fill those needs.

Contact Us

Fairville Products, Inc

Fuel Right

41 Germay Drive,

Wilmington, DE 19804

Phone: (302) 425-4400

Email: sales@fuelright.com

Web: http://FuelRight.com

Upcoming Events

VISIT US! NOVEMBER 12 - 14

2024 International Workboat Show

Booth #1660

Morial Convention Center

New Orleans, LA

CLICK HERE FOR DETAILS